THE INVISIBLE FOUNDRY:

DESIGNED TO HAVE A MINIMUM ENVIRONMENTAL IMPACT

“GREEN” PHILOSOPHY

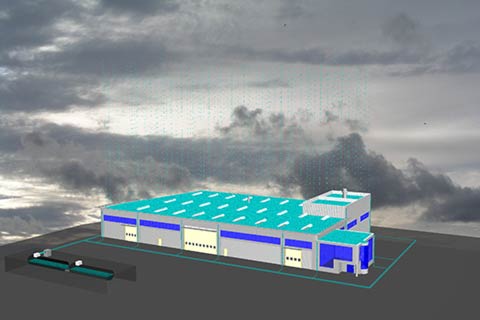

One of the advantages of the GDC Cast foundry is that … it does not look like a foundry.

It was given permission to build close to the centre of Arzignano because the plant is “invisible” and the ecological impact is reduced to a minimum. The foundry was designed and implemented to have a very low environmental impact, at a time when ecology and the wellbeing of the environment we live in are very topical subjects.

The DisaMatic melting facility, latest generation, has two induction furnaces which produce very little waste compared to conventional ones. In addition, initial selection of the raw material is rigorous, only providing top quality, pure cast iron.

The plant permits better suction of the earth and is monitored by a dust detection probe which, with a breakage (that has never happened so far) of the suction sleeve, generates an alert immediately. Another detail regards cooling closed and not with the bottom open.

Many people ask why our foundry releases no smoke. The answer is that we maximise control of emissions into the environment of particulate matter but also of smells and noise. That is why we are absolutely ecofriendly and “invisible”.

Control of fine dust is also guaranteed when raw materials are unloaded, in a specific pressurised area. When vehicles enter the foundry, the raw materials are collected in the pressurised warehouse and unloading is monitored to detect any possible radioactive substances present. Moreover, lorries are connected to aspirators to have control over an fine powders.

WATER MANAGEMENT WITH RAINWATER COLLECTED AND REUSED

A fundamental aspect of our interest in the ecological matters is our tendency to reuse. 98% of waste is reused in the production processes. This philosophy is also applied to the water management system. Water is needed to prepare the “sand” and for cooling during beating in the rotating drum. Still with low environmental impact in mind – part of the company policy of GDC Cast Spa, – a part of the water needed comes from a stagnant rainwater tank stored. The rainwater is collected in tanks on the roof and is then used in the plant.

The presence of an internal warehouse is another important environmental aspect for GDC Cast. Warehouses are usually in the open, not covered, and the cast iron is at the mercy of the weather. Besides generating dusts and other micro-particles, this allows rust to form and harmful substances are discharged into the ground. All things that are not admissible in GDC Cast.

All this makes GDC Cast a “green” company, careful ecologically and minimising the environmental impact