GDC CAST

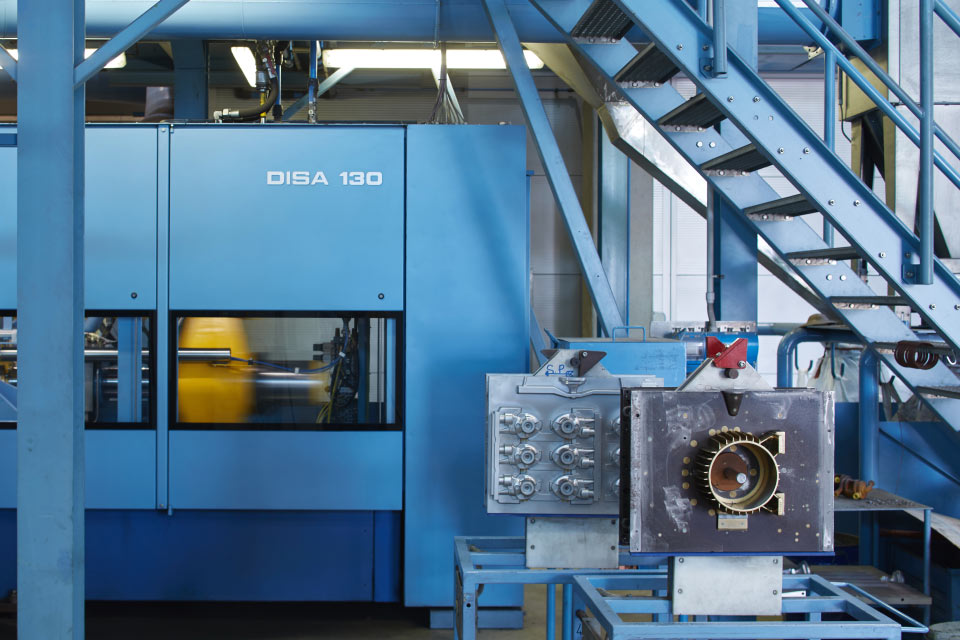

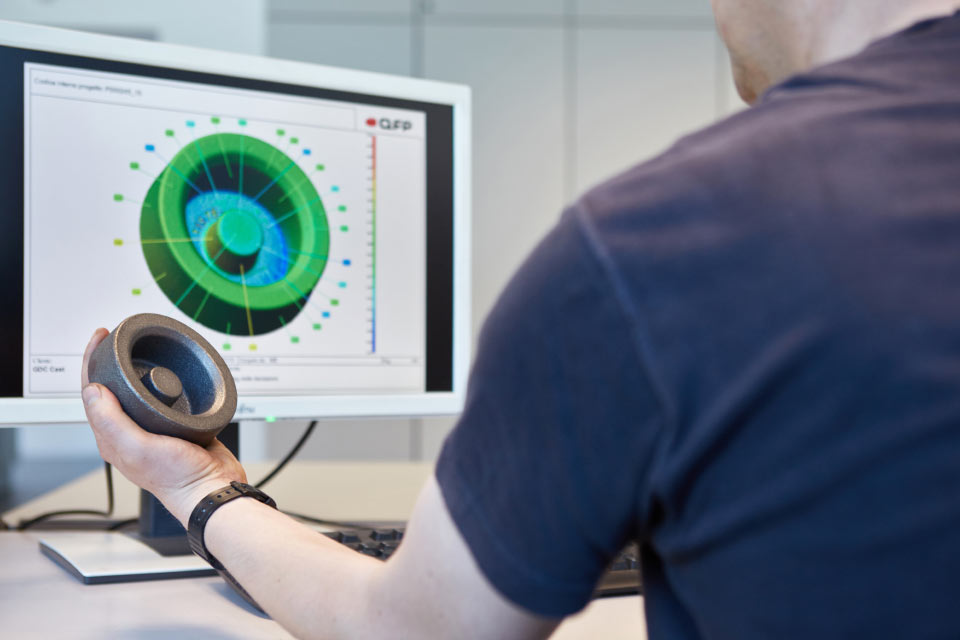

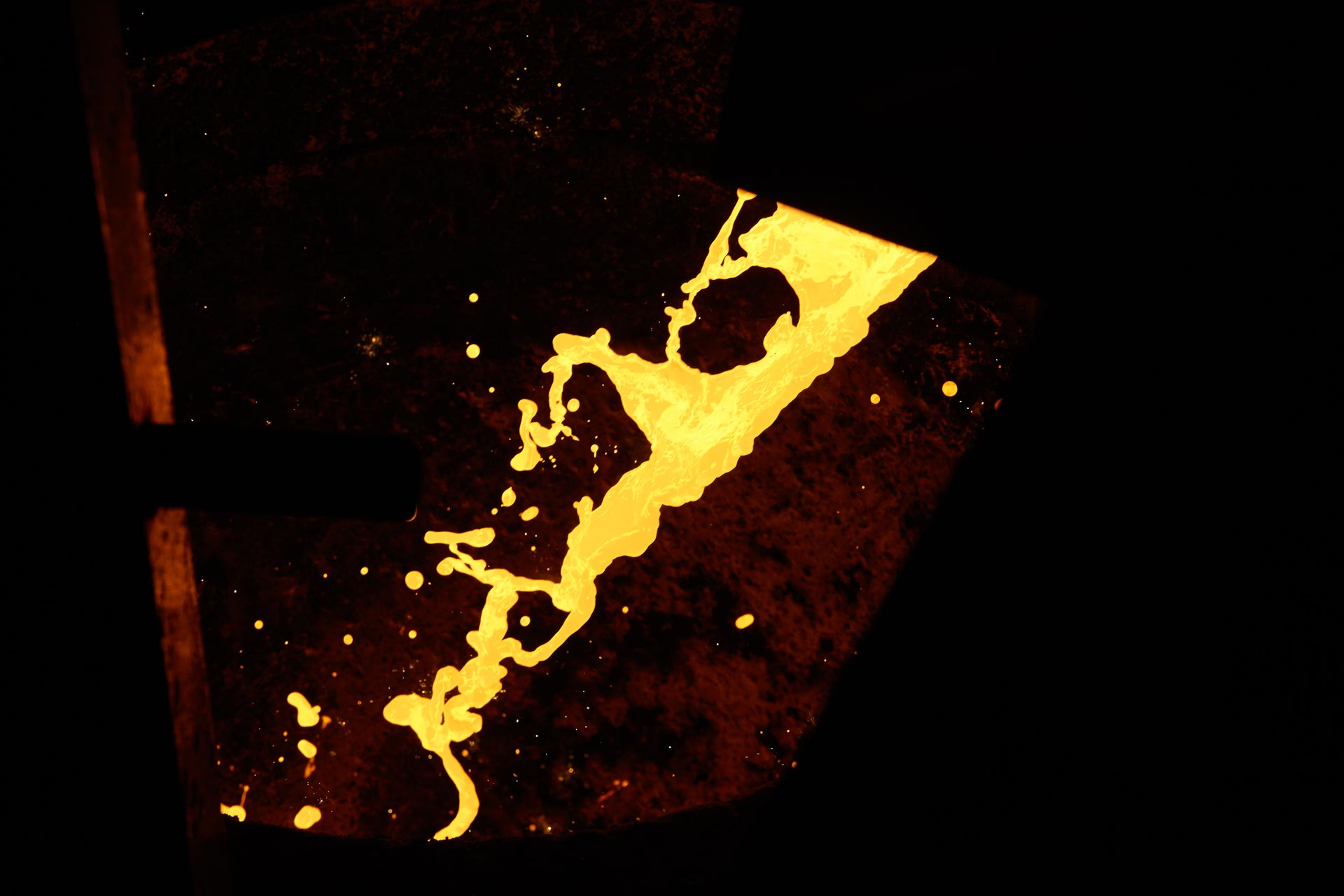

GDC CAST is a cast-iron foundry with cutting-edge technology, reliable top quality production and a low environmental impact.

GDC Cast Spa, located in the industrial area of Arzignano (VI), is part of ISGEV Spa, which has been designing and producing electric motors since 1948, and is present on the Italian, European and American markets with its reliable, top quality motors.

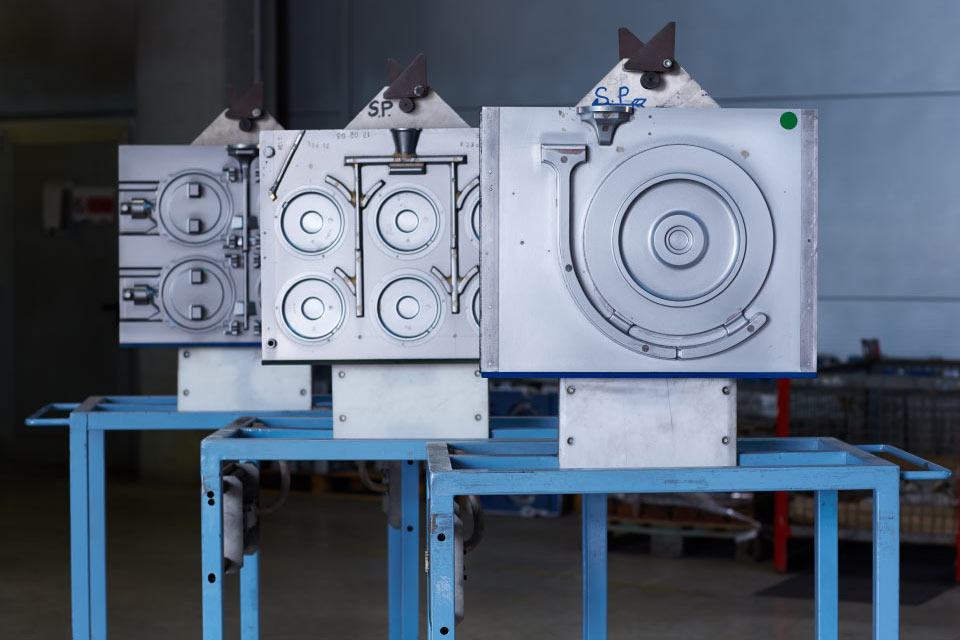

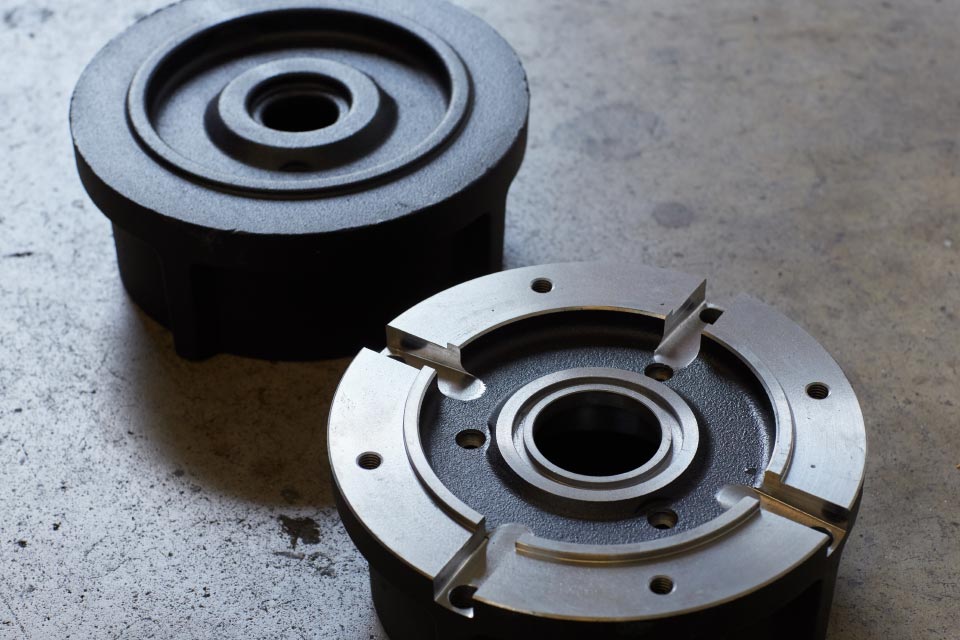

GDC stems from the ISGEV need to have guaranteed, reliable, continual production of the primary cast iron and aluminium components of its electric motors; to reduce its dependence on external suppliers, have more flexible management and maintain, for ongoing improvement, the product’s top quality standards.

Its goal has always been to create a highly automated foundry; to satisfy not just the internal ISGEV Spa demand, but also that of new clients needing reliable production, continuously researched and innovated, matched with a top quality level.